High Voltage Electric Composite Strain pin Insulator

High Voltage Electric Composite Strain pin Insulator

Product Introduction

A pin insulator is a component that supports or suspends a wire and forms electrical insulation between the tower and the wire.

A patent-designed puncture structure can penetrate the wire insulation layer in the in-line slot to form an electrical connection.The unique ark-starting fork is closely connected with the upper end of the insulator and the other end is the discharge end, forming a discharge gap with the ground electrode installed on the lower end of the insulator.And an insulating cover covers all exposed parts of the upper end of the insulator except the discharge end of the arcing fork.

Under normal condition, the discharge gap of lightning insulator does not operate.The gap between arcing fork and grounding electrode can be broken down and a short circuit channel can be formed only when the lightning overvoltage exceeds the regulation.The connected power-frequency arc burns on the arcing fork of the clamping line, releasing overvoltage energy to protect the wire from burns.

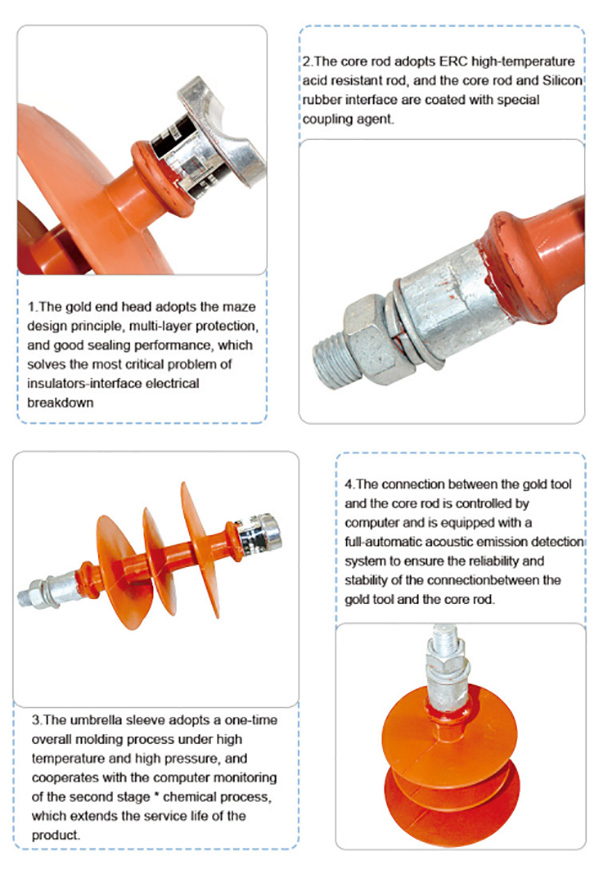

Product features and advantages

1.The silicon rubber shed booster is smooth and compact

2.Perfect hydrophobic performance, good resistance to aging, tracking and erosion.

3.High-strength acid-resistant FRP rod ensures the reliability of composite insulator.

4.The arcing corona ring well distributes the electric field along the insulator’s axe to prevent electric fainting phenomenon and secure the insulator from heavy damage in end fitting in case of flashover.

5.The end fitting and FRP rod are connected with imported end-fitting crimping equipment ,ensures the mechanical performance of the product.

6.The unique end fitting sealing structure improves product sealing reliability.

7.The strict inspection measures ensure the perfect quality of every product.

8.We can design and produce according to the drawings and detailed requirements of customers.

Technology parameters

| Product name | Product

Model |

Rated voltage |

Rated mechanical bending load |

Structure height H (mm) |

Minmun arc distance |

Min. creepage distance (mm) |

Lightning impulse voltage (kV) |

P.F. wet withstand voltage (kV) |

|

|

|

|

|

|

|

|

||

| Composite

pin Insulator |

FPQ-20/20T | 15 | 5 | 295 | 195 | 465 | 110 | 50 |

| FPQ-35/20T | 35 | 20 | 680 | 450 | 810 | 230 | 95 | |

| Composite cross-arm Insulator | FSW-35/100 | 35 | 100 | 650 | 450 | 1015 | 230 | 95 |

| FSW-110/120 | 110 | 120 | 1350 | 1000 | 3150 | 550 | 230 | |

| Composite

tension Insulator |

FXBWL-15/100 | 15 | 100 | 380 | 200 | 400 | 95 | 60 |

| FXBWL-35/100 | 35 | 100 | 680 | 450 | 1370 | 250 | 105 | |

| Composite

post Insulator |

FZSW-15/4 | 10 | 4 | 230 | 180 | 485 | 85 | 45 |

| FZSW-20/4 | 20 | 4 | 350 | 320 | 750 | 130 | 90 | |

| FZSW-35/8 | 35 | 8 | 510 | 455 | 1320 | 230 | 95 | |

| FZSW-72.5/10 | 66 | 10 | 780 | 690 | 2260 | 350 | 150 | |

| FZSW-126/10 | 110 | 10 | 1200 | 1080 | 2750 | 500 | 230 | |

| FZSW252/12 | 220 | 12 | 2400 | 2160 | 5500 | 1000 | 460 |

Product Introduction

Product Show

(1) Quality Assurances

We have a strictly quality control process from the raw material to finished products. Advanced testing lab to make sure products quality and improve our creative ability. Quality and Safety is the soul of our products.

(2) Excellent Services

Many years of manufacturing experience and rich export business help us to establish a well-trained sales service team for all customers.

(3) Fast Deliveries

Strong manufacture capacity to satisfy urgent leading time. It is around 15-25 working days after we receive the payment. It varies according to the different products and quantity.

(4) OEM ODM and MOQ

Strong R&D team for quick new products’ development, we welcome OEM, ODM and customize request order. Whether selecting a current product from our catalog or seeking engineering assistance for your application. You can tell us about your sourcing requirements.

Normally our MOQ is 100pcs per models. We also produce OEM and ODM as you requirement. We are developing worldwide agent.